The workhorse of the Defiant200 metal 3D printing system is the printhead. The printhead is more complex than many 3D printers but by breaking it down into it's individual functions you will be able to understand how it works.

The Defiant200 printhead is a 6 station multi-nozzle assembly. Only one nozzle is engaged at one time for the particular material being deposited into the furnace. Two nozzles are used per material. A fine 0.8mm nozzle and broad 5mm nozzle. This allows fine detail to be captured while allowing larger areas to be filled in quickly.

The Defiant200 printhead is a 6 station multi-nozzle assembly. Only one nozzle is engaged at one time for the particular material being deposited into the furnace. Two nozzles are used per material. A fine 0.8mm nozzle and broad 5mm nozzle. This allows fine detail to be captured while allowing larger areas to be filled in quickly.

Axis

|

The printhead is able to move in 4 axis.

The X and Y axis are controlled by external stepper motors mounted in the 3D printer frame. They provide motion to the printhead through a CoreXY arrangement. Two timing belts are run around the outer frame and attached to either side of the print head through a tensioning mechanism. This arrangement reduces the moving weight of the print head while allowing for quick movement. The U and V axis are controlled by two stepper motors mounted inside the printhead. The U axis raises and lowers the upper plate of the printhead. The rotary column is mounted underneath with each nozzle mounted on a linear rail on the column. To change the nozzle the U axis rises up and the V axis rotates to select the requested nozzle. |

Nozzles

|

Each nozzle has a small hopper at the top with a vertical bore that runs down to the nozzle. The powder only ever moves in a vertical motion from top to bottom reducing the potential for blockages in the powder path. Pictured is the 0.8mm fine nozzle in the printing position.

When a nozzle is engaged the other nozzles are each positioned over a loadcell. This allows the printhead to determine the mass of powder left in each hopper. If the mass falls below a pre-determined value then the print head will stop printing and run through an automatic filling operation from the larger hoppers at the side of the Defiant200 printer. The nozzles dispense powder through high frequency vibration. |

|

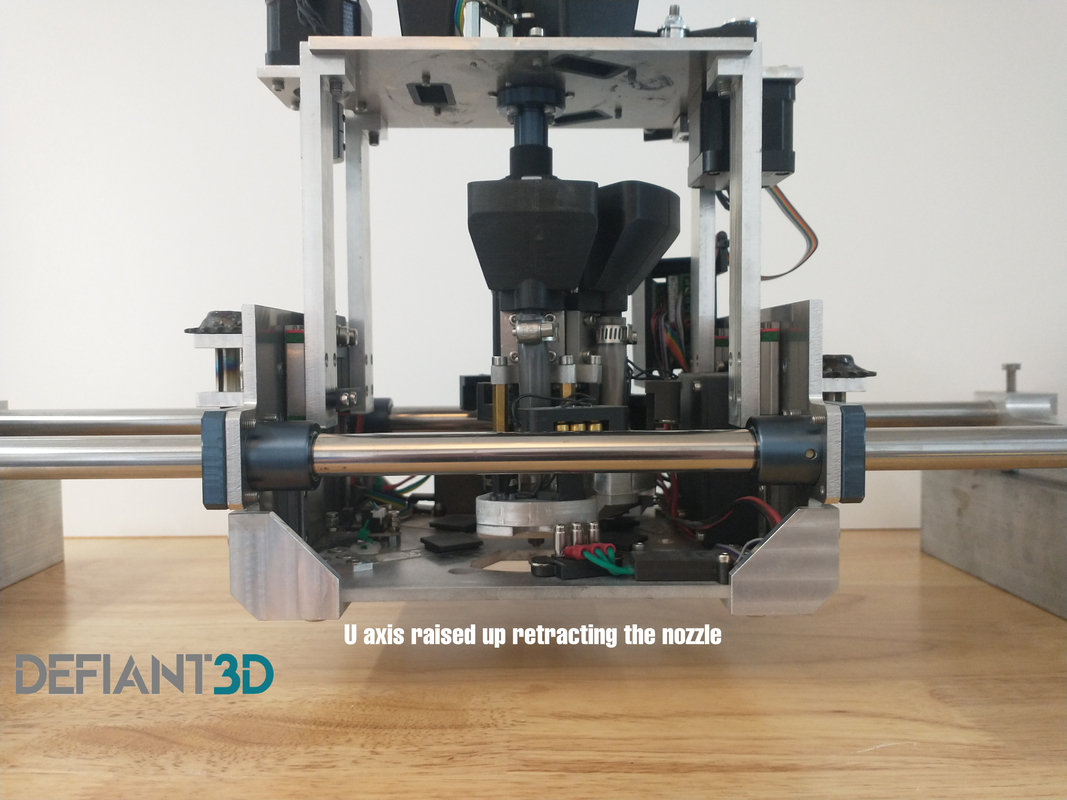

Here the U axis has been raised up allowing the nozzle to retract into the printhead. The print head can then be safely moved around the print area without disturbing powder already laid down in the print bed.

The V axis can also now be rotated to select a different nozzle if required. If a nozzle requires replacement then only 4 captive bolts have to be unscrewed and the nozzle assembly can be removed from the printhead. |

One final view!

|

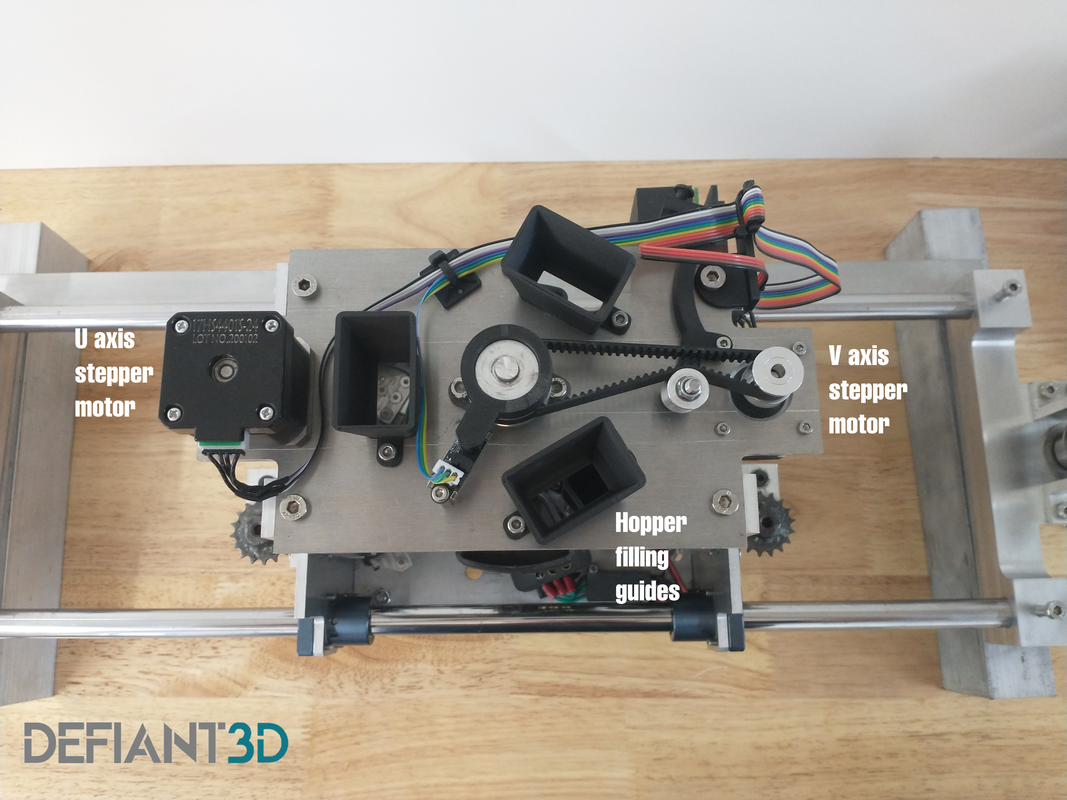

The stepper motors for the V and U axis are mounted to the top plate of the printhead along with the bearing mechanism to allow the multi-nozzle column to freely rotate.

The hopper guides line up with the large hoppers at the side of the Defiant200 printer to ensure the powder flows down into the smaller nozzle hoppers |